Introduction

Schoolhouse Condominium (Boston, MA) installed a new chiller/condenser system and excessive structural vibration and noise resulted both within the building as well as at the outdoor condenser. A number of 90 degree pipe bends were created in this process and this change was the suspected cause of the excessive vibration.

In addition, piping from the chiller to the condenser unit was rigidly connected to the building which could easily cause substantial structure-borne vibration and noise.

After substantial analysis and deliberations, a number of changes were made to reconfigure piping, orientation of the chiller unit, and to vibration isolate refrigerant piping at locations within the building. Piping reconfigurations consisted mainly of reducing the number of 90-degree bends that can cause pulsations of the refrigerant and resonances in the overall piping system. Spring isolation hangers were installed in order to avoid direct contact of piping with the interior of the building.

At your request, I measured noise and vibration on September 18, 2006 at various locations within the building and outside near the condenser unit to quantitatively assess the improvements.

Chiller Noise/Vibration

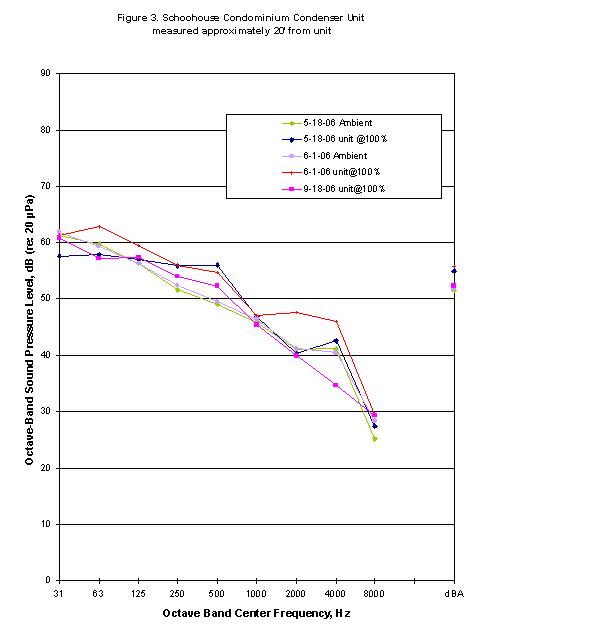

Figure 1 shows measured vibration levels in your bedroom and office before and after treatments. This data shows vibration velocity reductions of 17 dB at 125 Hz in your bedroom and office. These measured improvements are quite large and indicate that the treatments and various adjustments were successful.

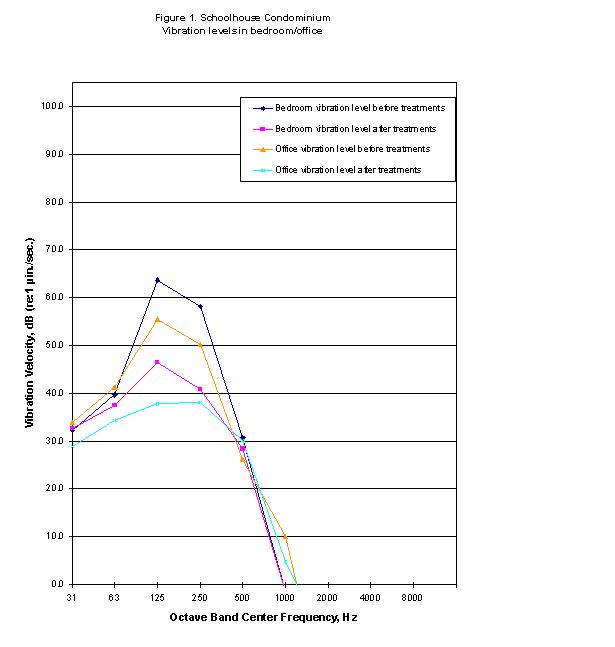

Since chiller noise is still audible in your bedroom, I conducted additional tests to determine the structure-borne and airborne noise contributions. The first step was to measure chiller noise in the mechanical room. The second step was to shut off the chiller and generate pink noise through a loudspeaker system with the same frequency spectrum and amplitude as the measured chiller noise. This test simulates the noise of the chiller, but with no structural component. Figure 2 shows measured loudspeaker and chiller noise in your bedroom. The fact that the loudspeaker spectrum is substantially lower than the measured chiller noise indicates that the problem is not primarily due to airborne noise. Consequently, to further reduce chiller noise in your bedroom, additional vibration isolation will be required. There are still a number of vibrating pipes and electrical conduit that are rigidly connected to the walls and ceiling of the mechanical room. I recommend that those connections be isolated using spring vibration hangers with appropriate load-bearing characteristics.

It is unclear how much, if any, vibration and noise reduction can result from these measures. Please note that recommended Noise Criteria for bedrooms ranges from NC 25 to 40. Measured chiller noise is now at NC 30 which is towards the low end of the range of acceptable levels.

Outdoor Condenser Noise

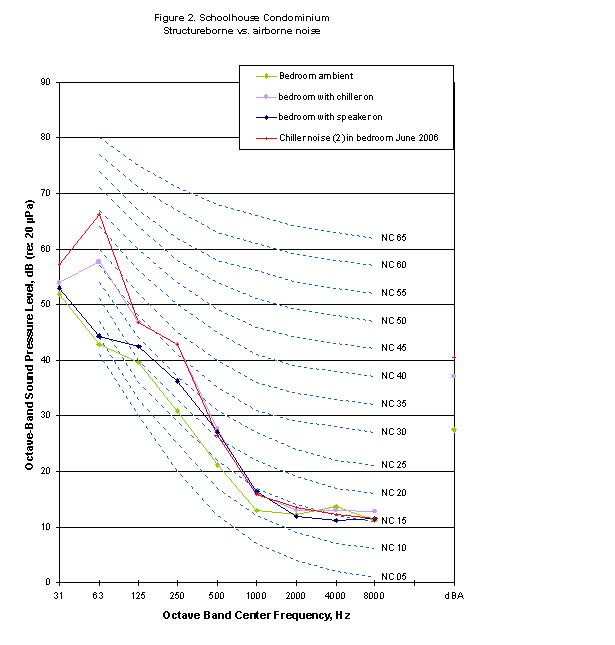

The noise levels generated by the condenser essentially have not changed since the installation of the new condenser unit except for a rattling noise which was due to excessive vibration of the piping near where the piping connects to the unit. Previous noise measurements showed that the rattling sound did not substantially increase the overall condenser noise level, but the rattling sound was quite noticeable. Since the various treatments have been installed, the rattling noise outside has essentially gone away. I measured condenser noise levels again, for comparison with the previous measurements, as shown in Figure 3. This data shows that condenser noise is very close to Bostonís nighttime 50 dBA limit. In addition, it is clear from these various sets of measurements that ambient noise influenced them to varying degrees. If the ambient noise level were lower, measured condenser noise would probably be somewhat lower as well.