Introduction

David Coate Consulting (DCC) analyzed exhaust noise issues at Velcro’s Somersworth, New Hampshire manufacturing plant. Two exhaust ducts ventilating the dryer area of the plant that penetrate the roof structure were producing high levels of noise outdoors causing complaints from the adjacent community. DCC recommended and specified the two silencers shown in the above photograph. Subsequent noise measurements indicated very substantial noise reduction which eliminated complaints from the community.

Exhaust Noise Measurements

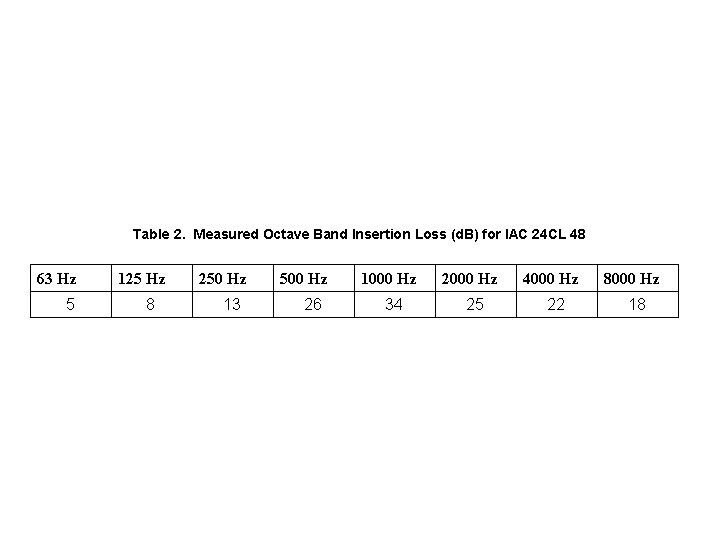

On 4/30/2010 I visited the site and measured exhaust noise levels at various locations. Measurements were obtained at two locations on the roof to determine the drop-off rate of the exhaust noise and two additional locations to roughly determine the directivity of the noise. Exhaust noise is directional, particularly at mid and high frequencies because of the orientation of the exhaust outlets. Figure 1 shows these two measured spectra.

Environmental Noise Modeling

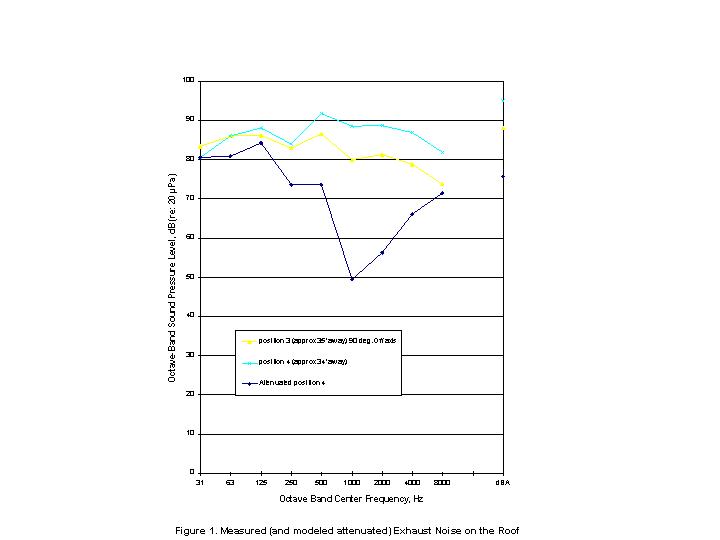

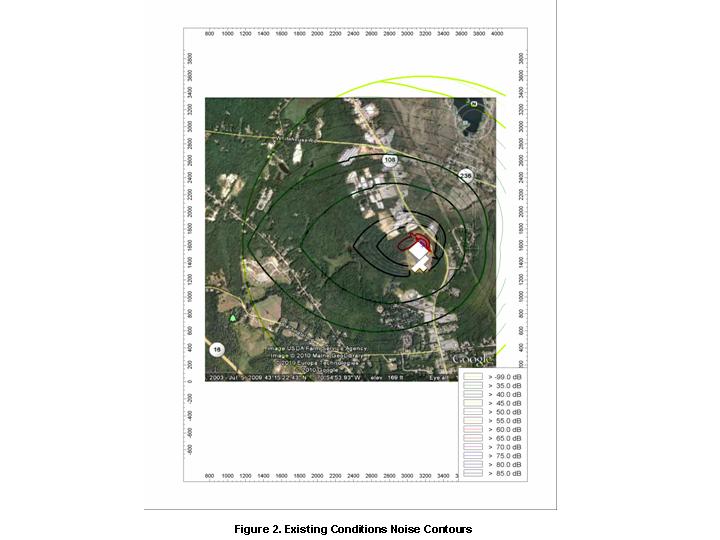

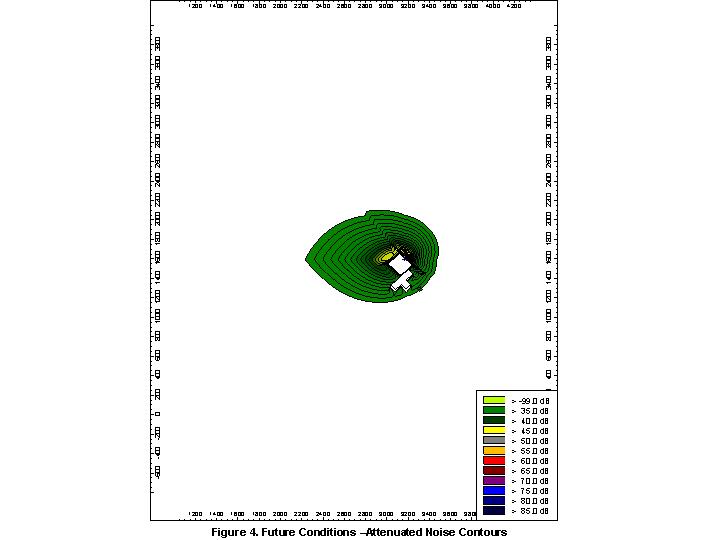

DCC used environmental noise prediction software to model the diffraction (shielding) effects of the plant building, measured exhaust directivity, as well as distance attenuation and atmospheric absorption. Figure 2 shows the results of this modeling exercise. These noise contours can be used for comparison against the community noise measurements, for showing potential areas of impact, and resulting changes after employing attenuation. Figure 3 shows the same noise contour data, except without the base map for ease of comparison with attenuated noise contours.

Data from Figure 2 shows that modeled plant noise levels at 243 Old Rochester Road are approximately 40 dBA, while actual noise measurements at this location were 41 dBA, so modeled noise levels are in reasonable agreement with measured values.

Exhaust Attenuation Modeling

Option 1 Duct Liner

Various techniques are available to attenuate the exhaust noise including the use of acoustical duct liner, as well as industrial/commercial silencers. All mufflers/silencers operate on the same basic principal of introducing acoustical absorption into the airstream. Some silencers have fins or internal chambers also covered with acoustical absorption in order to increase the amount of surface area of acoustical material. In addition, mufflers generally will increase back pressure to varying degrees because of increased restriction of airflow. An important non-acoustical issue is how much that airflow restriction may affect the operation of the fan units and overall performance of the system.

Acoustical duct liner, typically consisting of fiberglass or closed cell foam, has high sound absorption properties and the overall performance is dictated by how long the treated duct segment is. Since in this case the two vertical duct segments which pass through the roof are quite long, there is a potential opportunity to obtain a substantial amount of attenuation using duct liner.

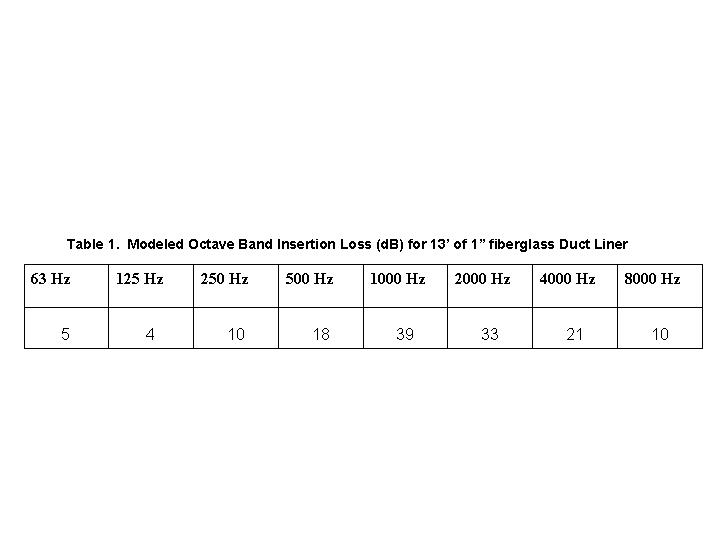

Assuming 1” thick fiberglass duct liner of 1.5 lb/ft3 density, the resulting modeled attenuation for 13 linear feet of installed treatment is as shown in Table 1.

The results in Table 1 show a substantial amount of attenuation, particularly in the mid-frequencies which would significantly reduce overall A-weighted noise levels (by approximately 19 dBA) in the community. Applying this reduction to the noise levels measured on the roof results in the dark blue spectrum shown in Figure 1.

Applying the insertion loss data to the environmental noise model results in the noise contours shown in Figure 4. The modeled noise level at 243 Old Rochester Road is 21 dBA, which would likely be substantially below ambient noise levels.

Option 2. Industrial Silencer

Another attenuation method would be to install an industrial silencer. Silencers work on very similar principals as the duct liner option by introducing sound absorption material into the airflow except that typical silencer designs increase the amount of surface area of absorption material by using fins covered with absorption material. Potential drawbacks to industrial silencers include higher cost and increased pressure drop. Benefits include actual measured insertion loss values and robust construction resulting in known environmental performance.

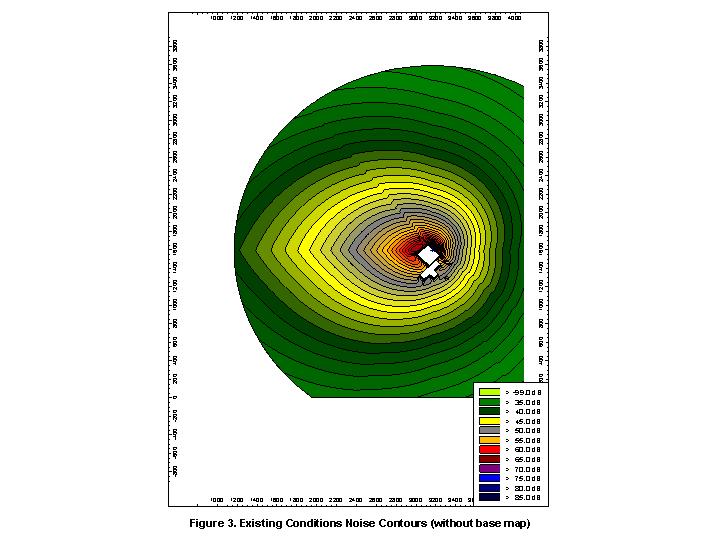

The Industrial Acoustics (IAC) silencer model 24CL 48 would provide attenuation similar to the duct liner option as shown in Table 2.